Introduction: A Greener Path for Logistics

Imagine a bustling UK logistics hub. Thousands of pallets moved daily. Forklifts humming. But the real noise? Ancient gas boilers churning out heat—and carbon. Rising energy bills. Stricter climate rules. The hub’s managers needed a rethink: a high-capacity heating system that ticks all the boxes for sustainability and cost.

Enter Megawave. We specialise in air source heat pumps that harness renewable power. And we’ve upped the ante by using a true zero-carbon refrigerant.

The Challenge: Heating at Scale

Moving from domestic boilers to industrial-scale renewable heating isn’t simple:

- High heat load: 3 MW peak demand.

- Temperature swings: UK winters can dip well below freezing.

- Carbon targets: Net-zero deadlines loom.

- Budget pressures: ROI must make sense in 3–5 years.

Our competitors have solutions. For instance, Fenagy’s recent 3 MW CO₂ heat pump in Belgium impressed many. But CO₂ (R744) comes with enormous system pressures and special lubricants. Great for some. Not ideal for every site.

Fenagy’s CO₂ System: Strengths and Limitations

We’ve got to give credit:

- Future-proof compliance with refrigerant regulations.

- 3 MW heating capacity delivered reliably.

- Automated controls for efficiency.

But:

- Super-high operating pressures make installation complex.

- Special Polyalkylene Glycol (PAG) lubricants add cost.

- Limited COP (coefficient of performance) in colder UK winters.

- Hefty maintenance needs.

Now, let’s talk about a different zero-carbon refrigerant – R290.

Why R290 Is a Zero-Carbon Refrigerant Game-Changer

R290 (propane) often slips under the radar. Yet it’s a true zero-carbon refrigerant with zero global warming potential. Here’s why it matters for big logistics sites:

-

Lower pressures

Unlike CO₂, R290 runs at familiar pressures. Easier installation. Standardised components. -

Better efficiency

The zero-carbon refrigerant unlocks higher COPs—especially at mild UK temps. -

Purely natural

No synthetic blends. No hidden GWP. Just propane. -

Regulation-friendly

By using a zero-carbon refrigerant, sites sidestep F-gas phase-down and costly future retrofits. -

Proven safety

Modern systems seal perfectly. Leak detectors and ventilation keep compliance simple.

R290 checks all the boxes. And at 3 MW scale? It’s a breakthrough.

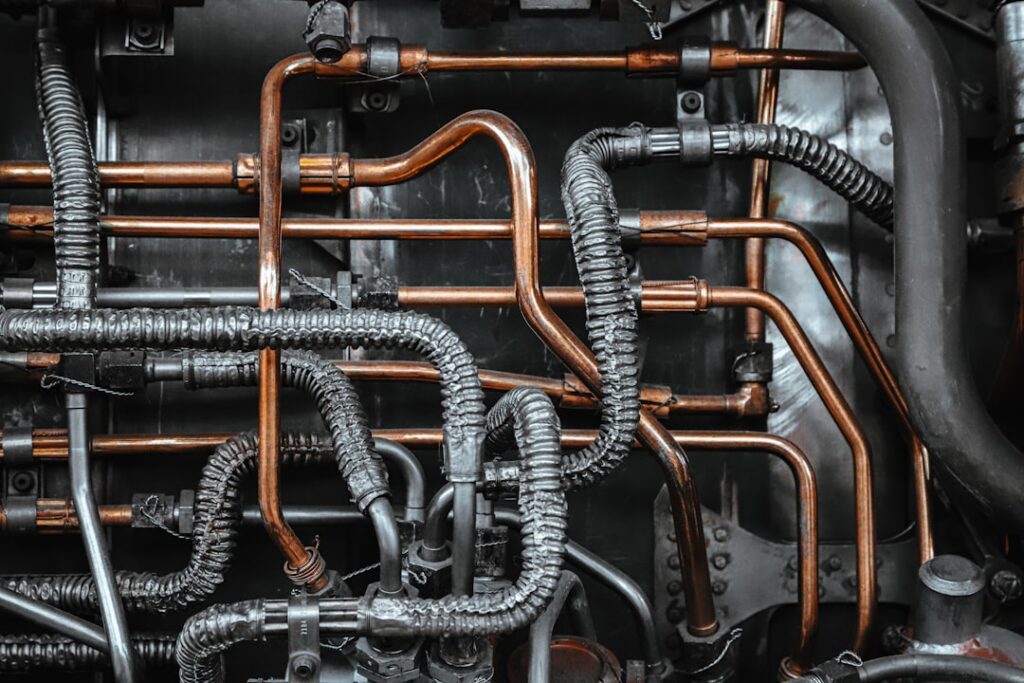

The Megawave Installation: From Plan to Performance

At the UK logistics hub, we designed and commissioned a bespoke R290 heat pump system. Here’s how:

- Detailed heat-load survey.

- 3 interlinked R290 modules, each rated at 1 MW.

- Smart controls tied into building management.

- Quick-connect hydraulic headers for easy maintenance.

- Expert installation by our accredited team.

- Seamless integration with existing on-site renewables (PV and wind).

We even arranged flexible finance options so the hub’s CFO could smooth CAPEX. Plus, we navigated government grants for zero-carbon refrigerant heat pumps—cutting upfront costs further.

Key Benefits in Action

Here’s what the logistics team saw in the first six months:

-

40% carbon savings

The zero-carbon refrigerant eliminated CO₂-equivalent emissions from boilers. -

£75 000 annual energy cost reduction

Higher efficiency means lower kWh usage. -

Solid ROI in under 4 years

Combined grants and finance made payback fast. -

Reliable performance at –15 °C

The zero-carbon refrigerant works seamlessly in freezing conditions. -

Simplified servicing

Standardised parts and our expert maintenance service keep downtime near zero.

All this while staying compliant and ready for future regs.

Overcoming Common Concerns

“Is propane safe at this scale?”

Yes. Modern R290 systems are hermetically sealed. We use multi-stage leak detection and automated shutdowns. The zero-carbon refrigerant is mildly flammable—but handled safely.

“What about noise and footprint?”

Our units run quietly. And they’re compact. You get 3 MW in a footprint no larger than a small shipping container.

“How does it cope in deep winter?”

With a zero-carbon refrigerant, COP remains above 2.5 down to –20 °C. That’s solid performance, even on frosty mornings.

“What if there’s a leak?”

Sensors trigger automatic isolation. Maintenance teams get alerted instantly. And thanks to the zero-carbon refrigerant’s natural profile, environmental risk is minimal.

The Bigger Picture: Renewable Heating Trends

The UK heat pump market is booming. Worth \$1.56 billion in 2023, rising 11.5% annually to 2030. SMEs and large sites alike shift to renewables. Why? Energy security. Carbon targets. Cost clarity.

A zero-carbon refrigerant strategy—especially using R290—matches this trend. It’s not a niche. It’s the new standard for reliable, efficient, large-scale heating.

Why Choose Megawave?

We don’t just drop in kit and leave. We offer:

-

Expert installation and maintenance services

Our team trains your operators. Service plans extend equipment life. -

Flexible finance options

Spreads costs. Fits most budgets. -

Government grant support

We handle applications for zero-carbon refrigerant incentives. -

Tailored system design

No two sites are identical. We plan for your exact heat load and future growth.

Megawave makes switching to a zero-carbon refrigerant straightforward. You get lasting comfort. Big savings. A greener footprint. And expert support at every step.

Conclusion: Decarbonise with Confidence

This logistics hub case proves it: you can scale a zero-carbon refrigerant heat pump to 3 MW and see real savings. No heavy penalties. No hidden headaches. Just efficient, eco-smart heating.

Ready to cut your carbon and slash bills? Let’s talk.